Thermal Imager

Prof. Subhananda Chakrabarti

The aim is to develop indigenous thermal imagers of various formats (320x256, 640x512 and 1kx1k) based on Gallium Antimonide and Gallium Arsenide technologies from wafer level. Along with, silicon electronics namely read-out-integrated-circuits (ROICs) will also be designed at IIT Bombay. They have countless applications from Forensic, Astronomy, military and security, industrial to Firefighting etc.

Any object whose temperature is above zero Kelvin radiates some amount of electromagnetic radiation across a range of energies. The amount of the radiated energy depends on the object’s energy and follows Stefan-Boltzmann law as E=σT4 where T is the temperature of the object in Kelvin and Stefan-Boltzmann constant σ = 5.6705 x 10-8 W/m2/K4. The energy spectrum of emission depends on the Temperature according to Planck’s Law and its peak emission wavelength can be determined by Wien’s approximation λmax= 0.290/T cm.K. “Infrared” band refers to the spectrum where biological life forms emit most light at wavelengths slightly longer than red. The IR spectrum can be of Near Infrared (NIR) of 0.75 – 1.4 µm, Short Wavelength Infrared (SWIR) of 1.4 – 3 µm, Mid Wavelength Infrared (MWIR) of 3-8 µm, and Far Infrared (FIR) of 15-1000 µm. For an average human body temperature of 36 deg Celsius, the peak emission is at about 9 micrometers which fall on the Long Wave Infrared region of the electromagnetic spectrum. Our eyes don’t see it as we lack necessary elements in the retina due to evolutionary reasons as infrared is a reality that exists behind all scenes. But we can sense through heat. Different material emits different energy depending on its emissivity. A material’s emissivity can range from zero (completely non-emitting) to 1 (Completely emitting). Emissivity also affected by the shape, viewing angle, temperature, and hence the wavelength.

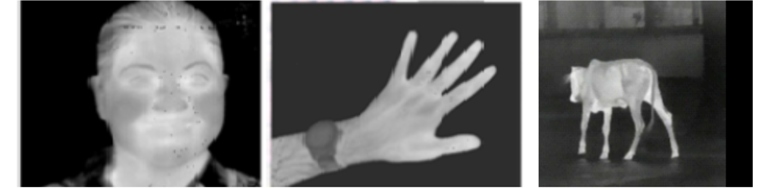

In a Thermal Imager, the infrared energy from the target is focussed by a lens on the detector array. The imager measures very small relative temperature differences and translates to a human-perceivable image on a monitor or viewfinder. They have countless applications from Forensic, Astronomy, military, and security, industrial to Firefighting, etc.

Detection can be direct where the photons directly translate to electrons such as Lead Selenide, Mercury Cadmium Telluride, etc, or thermal where it uses secondary effects on detector elements such as bolometers, thermocouples, etc. Early thermal imagers have several drawbacks like higher power consumption, requiring cryo cooling, large size weight, and high cost, etc. There are a lot of developments in improving these imaging Focal Plane Arrays involving material and growth optimization, Fabrication optimization in improving the NEDT (Noise Equivalent Difference Temperature) which is a measure of thermal sensitivity of the camera, and finally resulting in a camera package to be used in the field.

In the current generation of FPA, the imaging sensor is a two-dimensional array of various resolutions. Detector resolution is a measure of the number of pixels or the detector elements in the array represented as the number of Row x Column. For example, it could be 320 x 256 (has 81,920 detector elements) or 640 x 480 etc. Here, a 640 x 480 sensor will have better usable imaging quality. It will enable precise and reliable measurement from smaller targets from farther distances and hence sharper images. So the higher the detector resolution, the more is the accuracy and usability.